December, 2025

New Generation of Sonobuoy Technology for a New Threat Environment

For more than four decades, the U.S. Navy has relied on the SSQ-62 Directional Command Active Sonobuoy Sensor (DICASS) for short-range, high frequency active detection. Modern submarines are quieter, harder to detect, and operate at greater standoff ranges than ever before. The legacy sonobuoys have only marginally improved and no longer provide the reach or flexibility required for today’s contested undersea environment.

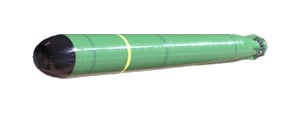

Introducing MCAPS: Three Times the Detection Range

The Medium-Frequency Combination Active Passive Sonobuoy (MCAPS) represents a decisive leap forward in U.S. Navy Anti-Submarine Warfare (ASW) capability. Compared to legacy SSQ-62 buoys, MCAPS delivers:

- 3x the detection range. Thanks to a modern advanced transducer, enhanced receive array, and next-generation battery system.

- Advanced active waveforms. Including both Continues Active Sonar (CAS) and traditional single-pulse transmission to improve recognition and tracking in contested environments.

- Integrated passive capability. MCAPS provides a narrowband passive acoustic capability, similar to the Navy’s SSQ-53 DIFAR buoy, which offers an increased detection range.

MCAPS is the only sonobuoy for ASW that provides active and passive acoustic capabilities at greater ranges than the U.S. Navy currently employs. Combining these features into a single sensor offers more flexibility for operators. It simplifies mission planning, and expands tactical options while reducing aircraft loadout, logistics complexity, and training burdens.

Doing More with Fewer Buoys: Cost Effective Modernization for a Demanding Fleet.

Sonobuoys are expendable, high-volume consumables. The U.S. Navy deploys approximately 250,000 buoys each year, more than all other nations combined. Using fewer sensors that deliver greater detection range is not only operationally advantageous, but also fiscally strategic.

With MCAPS, aircrews can detect, classify, track and if needed, prosecute submarines from greater distances and outside threat envelopes. Its extended range means fewer sonobuoys needed per field, reducing cost per mission and enabling the Navy to stretch its inventory further during periods of increased operational activity.

Additionally, MCAPS is built to NATO standards and is a perfect fit for worldwide coalition interchangeability, interoperability, and cooperative engagement against common targets of interest.

Strengthening America’s Industrial Base

Advanced Acoustic Concepts (AAC) has the ability to answer the Navy’s call to produce the needed inventory of sonobuoy technology now. Because of the high Technical Readiness Level (TRL), MCAPS will be fast to market while the Navy will experience cost avoidance for development and overall sustainment costs.

AAC, a Thales-owned company, is currently evaluating U.S. based manufacturing locations including existing Thales facilities to expand production capacity, create technical jobs, and further strengthen the U.S. supply chain resilience.

Testing & Demos Underway

MCAPS is currently being evaluated by the U.S. Navy and international partners. Stay tuned for details on upcoming demonstrations and operator engagements in mid-2026.

Advanced Acoustic Concepts (AAC) announced it has been appraised at Maturity Level 3 of ISACA’s Capability Maturity Model Integration (CMMI) for Development. This prestigious achievement, conducted by an independent appraiser, underscores AAC’s dedication to process excellence, continuous improvement, and delivering high-quality solutions to its customers.

Advanced Acoustic Concepts (AAC) announced it has been appraised at Maturity Level 3 of ISACA’s Capability Maturity Model Integration (CMMI) for Development. This prestigious achievement, conducted by an independent appraiser, underscores AAC’s dedication to process excellence, continuous improvement, and delivering high-quality solutions to its customers.

The SonoFlash mid-frequency combination active/passive sonobuoy Critical Design Review (CDR) was held the week of December 2, 2024. AAC representatives traveled to Sofia, France to witness briefs and an in-water acoustic test at Lake Castillon Reservoir. They were joined by Shawn Horigan, OPNAV N98 Air Warfare Division Sonobuoy Requirements Officer. The briefs and demonstration were conducted by both the French Direction Générale de l’armement (DGA) Program Director and Technical Director of Thales Program Management and Engineers.

The SonoFlash mid-frequency combination active/passive sonobuoy Critical Design Review (CDR) was held the week of December 2, 2024. AAC representatives traveled to Sofia, France to witness briefs and an in-water acoustic test at Lake Castillon Reservoir. They were joined by Shawn Horigan, OPNAV N98 Air Warfare Division Sonobuoy Requirements Officer. The briefs and demonstration were conducted by both the French Direction Générale de l’armement (DGA) Program Director and Technical Director of Thales Program Management and Engineers.